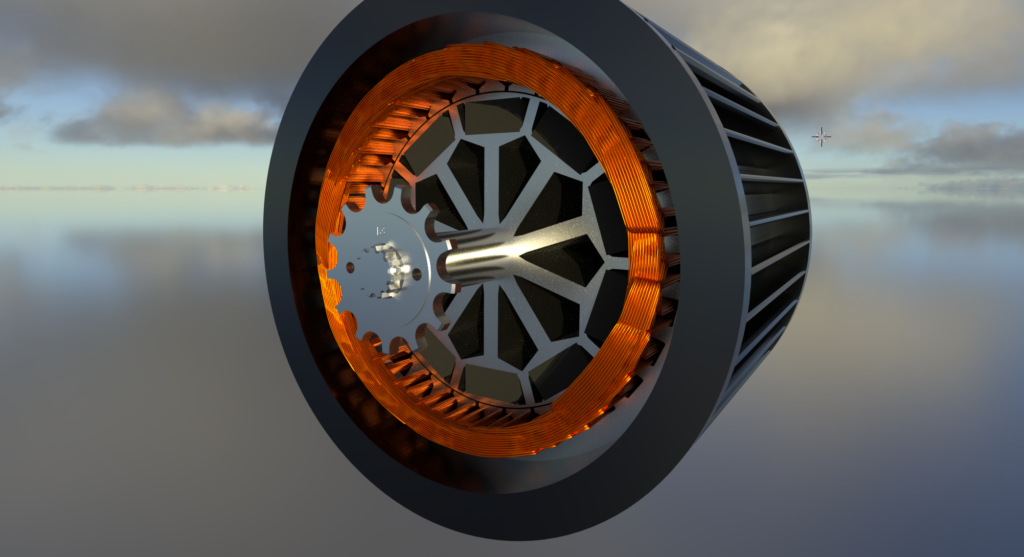

Ferromagnet assisted reluctance motor

Prototype motor information and goals

Motor information

- 11 kW nominal power and 45 kW peak power

- Has peak torque of 117 Nm and gets 45 kW already at 3700 rpm and keeps it until 7000 rpm

- Uses 48V system for easy and safe integration to vehicles even by hobbyist

- Uses European made components

- Case from Kurt Maier Motor-Press GmbH

- Motor stator and rotor from Voestalpine Automotive Components Dettingen GmbH

- Ferromagnets from Newland magnetics

- Motor axle, windings, end plates from Sähkö-Rantek (they will also assemble the motor for highest quality)

- Motor geometry optimized for high torque and power production

- Motor weight will be around 20 kg

- Motor windings will use vacuum pressure impregnation for long life

Motor goals

- Have very low carbon emissions from production

- Use sustainable materials (possible with ferrite magnets)

- Have very long lifetime 20-30 years with minimal maintenance (possible with vacuum pressure impregnation, hard anodized coating of exterior parts, with usage of high quality bearings and having discharge brushes to prevent ground problems)

- Produce high torque and power but still be efficient at lower loads. Simulations expect over 95% efficiency even with this lower voltage and usage of ferrite magnets

- Have easy way to install to many types of electric vehicles like motorcycles, boats and working equipment

- Show that long lasting sustainable motors have better future than motors made cheaply in countries that don’t care about environment or sustainablity